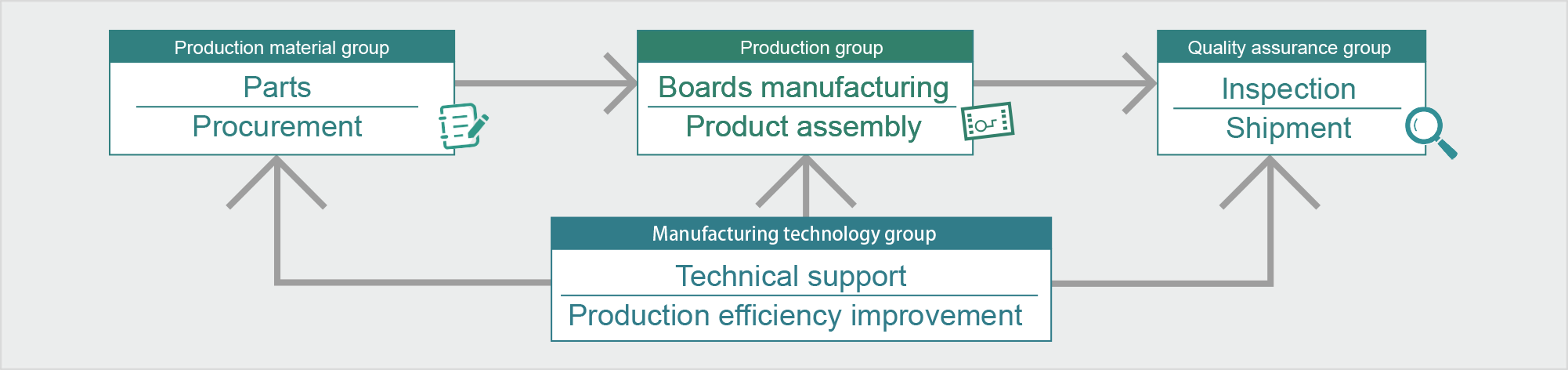

Production system at mishima plant

Production material groupParts procurement/Production management

It is available for us to give some suggestions like replacing parts, cost-cutting, and so on.

We manage parts and boards production, such as receiving orders, ordering, production control and inventory control.

Based on the knowledge and experience we have cultivated up to now, we can respond to the customer’s request using the specially-developed sales management system by a small number of people.

Production groupBoards manufacturing/Product assembly

Specialists suitable for each mounting process play an active role

Efficient production is possible by dividing the mounting process and specializing in specific work. Even while producing more than 1.200 models a year, we can instantly search for production data and schedules with the specially-developed sales management system.

Quality assurance groupInspection/Shipment

Visual inspection of all products and packing and shipping

We do pre-shipment inspection and packing.

We perform visual inspection of the mounted product boards based on the customer’s instruction and thoroughly prevent the outflow of defective products.

Manufacturing technology groupTechnical support/Production efficiency improvement

Design and production of original production line

We improve the production efficiency of boards manufacturing, provide technical guidance and control, and maintain equipment.

We maintain a system in which boards manufacturing can be performed smoothly by providing instructions on how to use equipment, instruction on maintenance, etc., and responding to problems that occur at the manufacturing site.

Head office of ProductionProduction material group

This is the front group of Mishima plant for manufacturing PC boards.

Customer service, accepting and placing orders, production control, and stock control are done in this group.

It is available for us to give some suggestions like replacing parts, cost-cutting, and so on.

Purchasing service

There are more than 200 electronic parts manufacturer which are connected with us. If you have problems to purchase those parts, we can help you to find and introduce companies, or purchase them for you. Also, it is available to purchase from Asian manufacturer through Shoritsu (Shanghai) int’l co., ltd.

Accepting orders / Placing orders

As following customer’s request, the person in charge is to be accepting order and placing order to make up for the shortage parts.

Ordering process is done effectively by using our original sales control system.

Accepting parts

We ensure traceability of parts because of bar-code sticker which is attached to each part after checking name and number of each part.

Stock control

In order to control each customer’s stock, every parts are to be classified and stocked by each customer and recorded in the inventory book.

It is available to answer the inventory status promptly and clearly whenever you need.

Production control

The person in charge of placing order is to decide delivery date as understanding both expected delivery date by customer and capable delivery date by us.

Parts positioning and fabrication

Parts are to be became in kit before positioned to each manufacturing process.

By being read the bar-code sticker, we ensure first-in first-out system and traceability of parts.

Parts which need fabrication before they are mounted are in same system as above. Those parts are positioned to each manufacturing process after the fabrication.

Head office of ProductionProduction group

Production group is the keystone of Mishima plant.

There are three teams, and each one is called the Automatic implementation team, the Robot implementation team, and the Assembly/ Checking team.

It is possible to have lean production by dividing production processes.

The Automatic implementation team

his group is for the process of automatic machine mounting and appearance check. We have three lines of automatic machine mounting.

There are nitrogen reflow ovens, and they make us possible to have high quality and equable mounting process. Automatic appearance check machines are applied for the appearance check.

自動実装チーム設備一覧

| LINE1 | |||

| LINE1 | 装置名称 | 装置型式名 | メーカー |

|---|---|---|---|

| クリームはんだ印刷機 | YCP10 | YAMAHA | |

| はんだ印刷検査機 | VP5200L-V | CKD | |

| ディスペンサー | YSD | YAMAHA | |

| 高速マウンター | YS12 | YAMAHA | |

| 異形マウンター | YS100 | YAMAHA | |

| N2リフロー炉 | NJ0611M-82 | エイテックテクトロン | |

| N2発生装置 | NE-20PS | コフロック | |

| N2PSA用コンプレッサー | SCD-110JCBD0 | アネスト岩田 | |

| LINE2 | |||

| LINE2 | 装置名称 | 装置型式名 | メーカー |

|---|---|---|---|

| クリームはんだ印刷機 | YCP10 | YAMAHA | |

| はんだ印刷検査機 | VP-5200L-V | CKD | |

| ディスペンサー | YSD | YAMAHA | |

| 高速マウンター | YSM20R-1 | YAMAHA | |

| 窒素リフロー炉 | NJ0611M-82 | エイテックテクトロン | |

| N2発生装置 | NE-20PS | コフロック | |

| スクリューコンプレッサー | Z155AS4-R | 三井精機工業 | |

| LINE3 | |||

| LINE3 | 装置名称 | 装置型式名 | メーカー |

|---|---|---|---|

| クリームはんだ印刷機 | YCP10 | YAMAHA | |

| はんだ印刷検査機 | Ysi-SP | YAMAHA | |

| 高速マウンター | YSM20R-1 | YAMAHA | |

| N2リフロー炉 | NJ0611M-82 | エイテックテクトロン | |

| N2発生装置 | 022-NE20PS | コフロック | |

| スクリューコンプレッサー | Z155AS2-R | 三井精機工業 | |

| LINE4 | |||

| LINE4 | 装置名称 | 装置型式名 | メーカー |

|---|---|---|---|

| クリームはんだ印刷機 | GPX-HD | FUJI | |

| はんだ印刷検査機 | VP-5200L-V | CKD | |

| 高速マウンター | XPF-L | FUJI | |

| コンパクト多機能装着機 | XP-243E | FUJI | |

| N2リフロー炉 | NJ06M-82-RLF | エイテックテクトロン | |

| N2発生装置 | BPN3-100LP | エア・ウォーター・ベルパール | |

| スクリューコンプレッサー | OSP-11M5ARN3 | 日立産機システム | |

| 外観検査装置 | |||

| 外観検査装置 | 装置名称 | 装置型式名 | メーカー |

|---|---|---|---|

| 卓上型高速外観検査装置 | BF-SRIUS | SAKI | |

| 3D外観検査機 | Ysi-V 3D | YAMAHA | |

| 射出成型機 | |||

| 射出成型機 | 装置名称 | 装置型式名 | メーカー |

|---|---|---|---|

| 竪型ロータリー射出成型機 | JT40REL Ⅲ | 日本製鋼所 | |

| 金型温度調節機 | MCL-25-X-J | 松井製作所 | |

| 清掃簡易型低速粉砕機 | MGL-100型 | 松井製作所 | |

| 大型プログラム定温乾燥器 | DOV-600PA | ASONE | |

| 除湿熱風乾燥機 マルチジェット | MJ3-15J-OP | 松井製作所 | |

| 測定顕微鏡 | MF-B3017B | ミツトヨ | |

| メタルマスク | |||

| メタルマスク | 装置名称 | 装置型式名 | メーカー |

|---|---|---|---|

| メタルマスク洗浄機 | SC-AH100-LV | サワーコーポレーション | |

| ピン打ち機 | |||

| ピン打ち機 | 装置名称 | 装置型式名 | メーカー |

|---|---|---|---|

| ストレートピン端子挿入機 | PIS-10-2010 | icrex (アイレックス) | |

| 90度曲げピン端子挿入機 | PIS-60-2010 | icrex (アイレックス) | |

The Robot implementation team

In robot implementation team, automatic soldering machines which are newly introduced are mainly applied for our production.

In the process of manual mounting and soldering mounting, parts which are hard to be mounted by machines are to be mounted by workers.

This process is done with automatic soldering machine in nitrogen gas atmosphere.

ロボット実装チーム設備一覧

| ロボットはんだ | |||

| ロボットはんだ | 装置名称 | 装置型式名 | メーカー |

|---|---|---|---|

| はんだ付けロボット | J-CAT400STELLAR+RSP | アポロ精工 | |

| はんだ付けロボット | mini-maxⅢ | 津々巳電機 | |

| ロボットはんだ付けライン | |||

| ロボットはんだ付けライン | モジュール型汎用自動組立機 | Smart FAB-D | FUJI |

| インライン式はんだ付け装置 | SR-IST・SR-SOR・SR-SPD | 昭立電気工業 | |

| セル生産式はんだ付け装置 | SR-IAF | 昭立電気工業 | |

| はんだ槽(RoHS) | |||

| はんだ槽(RoHS) | スプレーフラクサー | MXL-350Y | 日本電熱計器 |

| 窒素封入式はんだ装置 | ILF-350HB | 日本電熱計器 | |

| はんだ槽用N2装置 | |||

| はんだ槽用N2装置 | N2PSA用コンプレッサー | Z155AS-R | 三井精機工業 |

| (RoHS・共晶で共用) | |||

| (RoHS・共晶で共用) | N2発生装置 | NDLA-4200-TP | 日本電熱計器 |

The Assembly/ Checking team

Assembly/ Checking team is the process of mounting parts which are supposed be mounted in previous process.

It is also the process of assembly, and adjustment and checking.

As cooperating with robot implementation team, automatic soldering machines which are newly introduced are applied for our production in order to enhance operation efficiency.

A bed of nails is also available for functional check. It depends on each customer’s request.

We use robots for soldering in the process in order to enhance operation efficiency and improve our quality.

Post-mounted process

Soldering and mounting process of components by hand. Soldering is done by hand for parts that are difficult to implement by the automatic implementation team and the robot implementation team.

We have adopted soldering robots to improve work efficiency and quality.

Checking process

This is the process of checking of completed PC boards after mounting processes.

A bed of nails is also available for functional check.

We also write a program. It depends on each customer’s request.

Assembly process

Every PC board which has been checked in the checking process is to be assembled in this process.

We can incorporate PC board into product flame at customer’s request, and it can be shipped to the market.

組立・検査チーム設備一覧

| 設備 | |||

| 設備 | 装置名称 | 装置型式名 | メーカー |

|---|---|---|---|

| 基板分割機 | T-HX98D | ティエスティ | |

| 基板分割機 | T-MD22D | ティエスティ | |

| 基板分割機 | T-MS20 | ティエスティ | |

| インサーキットテスター | ZPC-5000 | オカノ電機 | |

| 恒温槽 | HIFLEX FX2300 | ETAC | |

| 定温乾燥機 | Dring Oven DX31 | Yamato | |

| 2液自動計量混合吐出機 | TSP-500-B-B | 日本ソセー | |

Manufacturing Engineering DivisionQuality assurance group

This group is checking and packaging of product before shipment.

Mounted PC boards are to be visually checked as following the design which is defined by a customer.

It prevents defective products from being shipped.

Packaging is done as following each customer’s packaging standard after the number of products is ascertained.

Manufacturing Engineering DivisionManufacturing Technology Group

This group is for improvement of productive efficiency, instruction and control of techniques, and maintenance of the equipments.

We also suggest cost-cutting by automated manufacturing.

We have manufactured more than 1000 different kinds of jig and tool.

This actual achievement can be applied in the processes of soldering, parts manufacturing, assembly of PC board, and so on.

In order to improve productive efficiency, cutting machine which is controlled by computer numerical control (CNC) is brought in for manufacturing high-quality jig and tool.

We also make cost-cutting suggestions which will be brought by jig and tool for functional check and automatic manufacturing.

組立・検査チーム設備一覧

| 設備 | |||

| 設備 | 装置名称 | 装置型式名 | メーカー |

|---|---|---|---|

| CNC切削機 | MODELA PROⅡ MDX-540 | ローランドDG | |

| CNC切削機 | MODELA MDX-50 | ローランドDG | |

| 卓上精密旋盤 | L-5200型 | コスモキカイ | |

| 小型フライス盤 | KC-Ⅱ | 小久保鉄工所 | |

| タッピングボール盤 | BT13SL | 日立工機 | |

| 3Dプリンター | MF-1000 | ムトーエンジニアリング | |

その他設備一覧

| 設備 | |||

| 設備 | 装置名称 | 装置型式名 | メーカー |

|---|---|---|---|

| レシプロ オイルフリー コンプレッサー | TFP110BB-10M5 | アネスト岩田 | |

| レシプロ オイルフリー コンプレッサー | TFP110C-10 | アネスト岩田 | |

| 冷凍式エアードライヤー | RAX15G | オリオン | |

| 冷凍式エアードライヤー | RAX15J | オリオン | |

| レーザーマーカー | LP-430U-160 | SUNX | |

| デシカント除湿機 | SGP-330 | 西部技研 | |

We will meet your needs! Please feel free to contact us.

TEL:+81-44-511-5511

FAX:+81-44-511-5513